gaugestools has a full line of fixed limit gages also called fixed limit gauges. Usually they are called GO NOGO gages, they are used to check threaded parts based pass/fail principle. The go gauge should go through the entire threaded parts, the NOGO gauge should be stopped not exceed three turns.If the go gauge passed the threaded parts,then we can judge that the maximum material condition of a part hasn’t exceeded. If the NOGO gauges stopped not exceeding three turns, then we can judge that the minimum material condition of a part hasn’t exceeded. Then we can come to a conclusion that the threaded parts are quality fine. We choose Gcr15-bearing steel as the material of gauges.

fixed limit gauges are the most effective way of checking threaded parts.

- the cost of fixed limit gages is not very high, especially gaugestools’s thread gages are very competitive.

- fixed limit gauges are easy to use and can check parts very quickly greatly saving labour cost.

- fixed limit gauges are very accurate.

Fixed limit gauges are primarily used to check dimensions. there are two kinds of gages, one is plug gages, the other is ring gauges. ring gages are used to check external threaded parts, plug gages are used to check internal threaded parts.

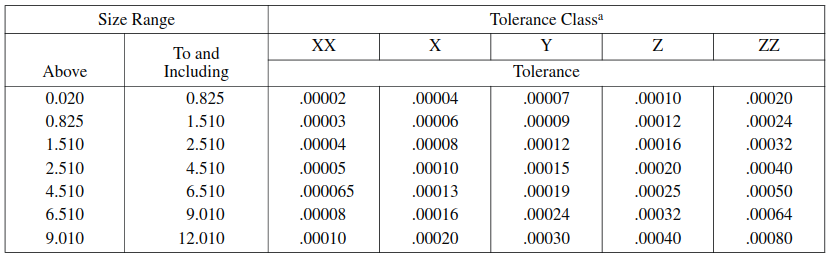

American National Standard Tolerances for plain Cylindrical Gages ANSI/ASME B1.2-1983(R2007)

some good tips for using fix limit gages

- The threaded parts which will be gaged should be free of burr and clean enough to avoid gaging interference

- When workers of calibration lab test the thread gauges, they control ambient temperature:(20+-1) °C, (55+-10)% relative humidity. As temperature and humidity both will affect the testing results. The temperature of gauges and the parts should be same. (20+-1) °C temperature and (55+-10)% relative humidity is the ideal environment condition . This effectively reduce any error because of thermal expansion.

- Gauges should be turned gently and slowly to the threaded parts without using too much force. It is the most important principle. If using too much force for gaging, the inspection results will not be correct, and it is possible that both the threaded parts and thread gauges will be damaged.

- After use,thread gauges need to be cleaned and re-coated with anti-rust oil, and stored in suited condition. Thread gauges should be stored far away of excessive heat, moisture and corrosive chemicals. By doing these, the life of thread gages will be greatly extended.

- Thread gauges are possible to be worn out, so they should be calibrated periodically to assure accuracy.

Tolerances apply to actual diameter of plug or ring. Apply tolerances as specified in the standard. Symbols XX, X,Y,Z, and ZZ

are standard gage tolerance classes. all dimensions are given in inches.